Automatic container fillers for low and medium productions

Our automatic container fillers have a throughput from 200 to 6000 containers / hour. Filling of all types of containers. (jars, bottles, demijohns...).

FR series automatic filler

The FR series automatic filler consists of a linear conveyor that receives the containers and drives them synchronously to the cavities of a servomotorized intermittent rotating starwheel, which moves them in its rotation to the different filling, capping and threading positions. The filling area has an interchangeable dispenser for the different volumes. While a container is being filled in one position, the previous one is capped and another one screwed in the following ones.

The filling nozzles are connected to the dosing system described separately.

Set of corresponding input and output tapes.

FL series automatic filler

In the FL series automatic filler the containers are received already arranged in a row of one, and properly aligned.

The infeed conveyor belt of the automatic container filler transports the containers to the filling area and places them under the dosing system.

The dosing system of the automatic container filler inserts the filling nozzles into the containers and discharges the corresponding amount of product into the containers.

The dosing system is equipped with several filling nozzles, so that several containers are filled simultaneously in each line cycle.

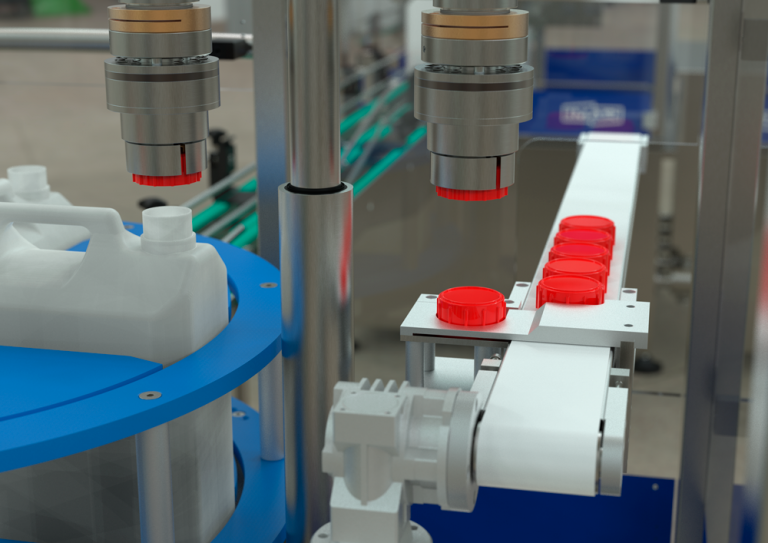

Once filled, the containers are transported by a conveyor belt to the cap application system.

The containers circulate under the capping system, and each one automatically removes a cap as it passes through. The containers then pass through the twist-on capping system which tightens the caps to the selected torque.

Once the closing process is completed, the containers exit in line through an outfeed conveyor belt to continue the process in other systems/devices eventually installed later.

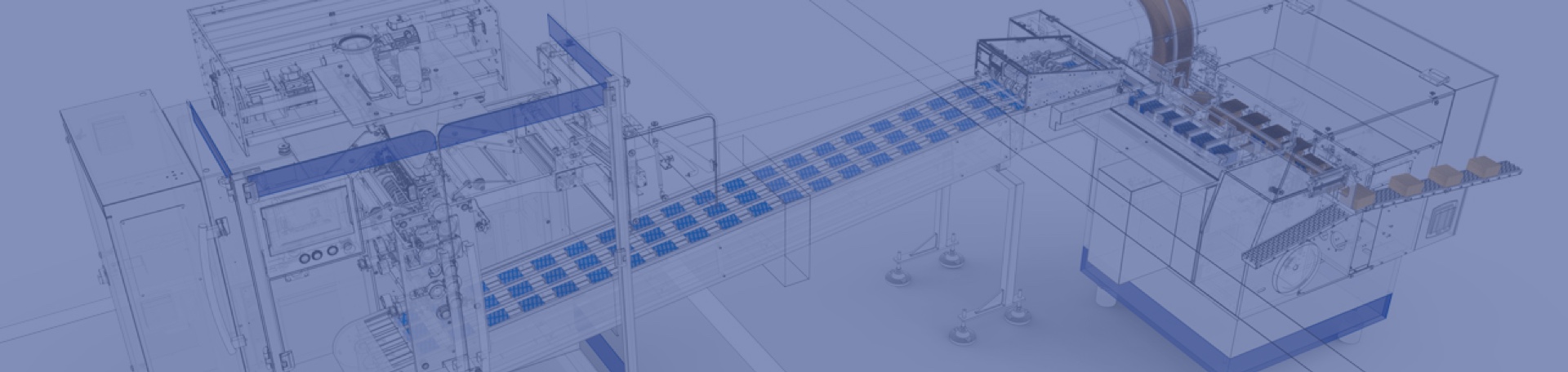

Automatic container filler accessories and options

The automatic container filler can be completed with complementary equipment such as conveyor belts, labeling machines or mosaic forming systems for shrink wrapping.

Like the rest of our packaging equipment, the automatics container filler can be equipped with any of the various dosing systems available in our catalog and thus adapt to the type of product to be packaged.